The Ultimate Guide to Cooler Oil Engine Systems for Diesel Engines

In the world of diesel engines, understanding the intricacies of the cooler oil engine is crucial for any business involved in the mechanics and maintenance of these powerful machines. Whether you're a spare parts supplier or an engine repair shop, knowing how cooler oil systems function and their impact on overall engine performance can greatly enhance your service offerings and customer satisfaction.

Understanding the Basics of Cooler Oil Engines

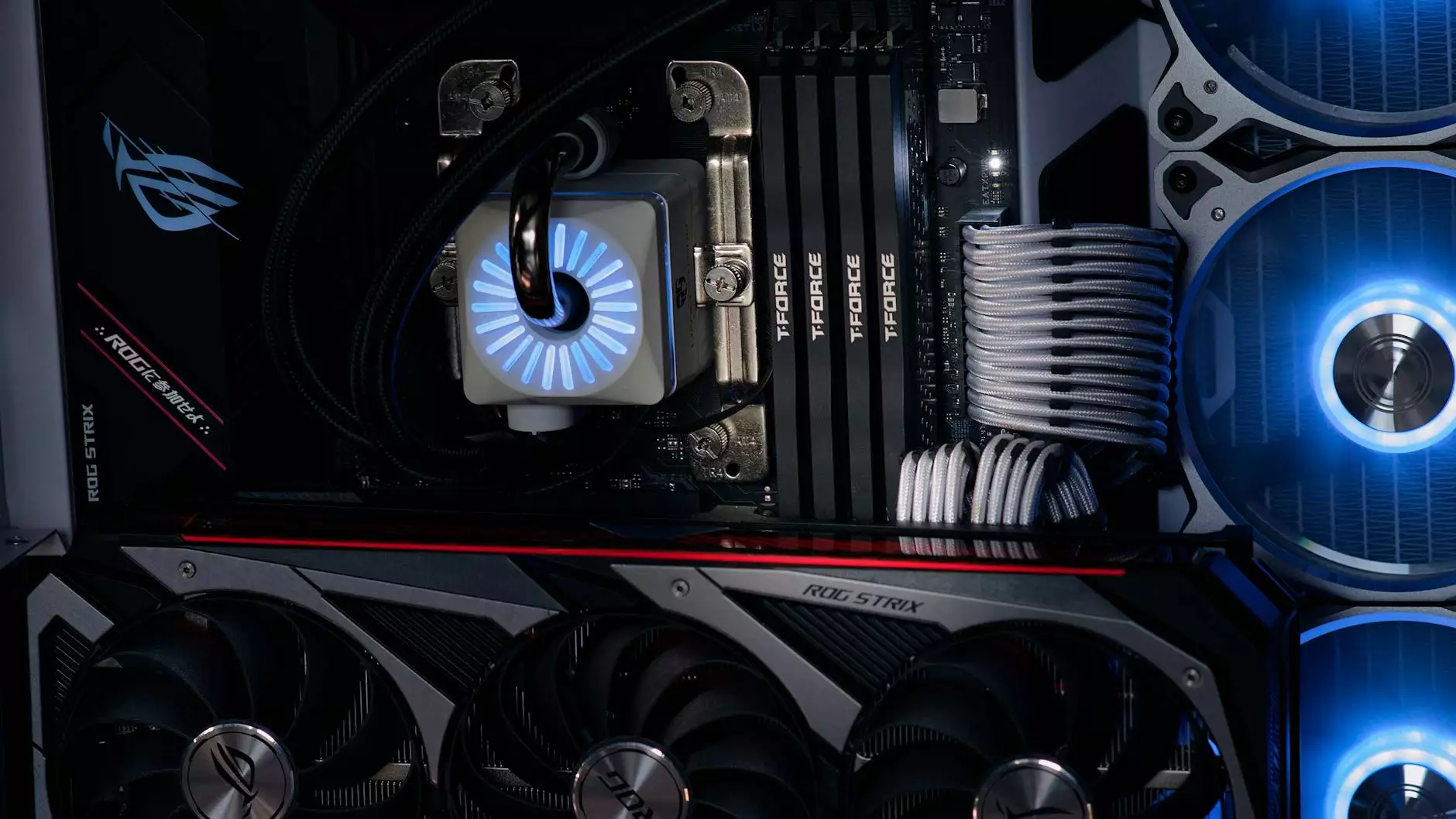

A cooler oil engine system is part of the larger cooling system that ensures engine oil maintains optimal temperature levels. Diesel engines generate a significant amount of heat during combustion, and without adequate cooling mechanisms, this heat can cause detrimental effects on engine performance and longevity.

What is a Cooler Oil Engine?

The cooler oil engine refers to components designed to decrease the temperature of engine oil. Effective cooling of engine oil is essential because it lubricates engine parts, reducing friction and wear. There are various types of oil coolers used in diesel engines, including:

- Air-Cooled Oil Coolers: Use air flowing through fins to dissipate heat.

- Water-Cooled Oil Coolers: Utilize coolant from the engine’s cooling system, often providing more efficient heat exchange than air-cooled versions.

- Plate & Frame Oil Coolers: Consist of a series of plates that create a large surface area for heat exchange, making them highly effective in limited spaces.

The Importance of Cooler Oil Systems in Diesel Engines

Every diesel engine is impacted significantly by the temperature of its operating fluids. High oil temperatures can lead to reduced lubrication efficiency, which can accelerate wear on engine components. In contrast, maintaining an optimal oil temperature ensures that your engine operates as efficiently as possible.

Benefits of Installing a High-Quality Cooler Oil Engine

Investing in a high-quality cooler oil engine system presents numerous advantages, including:

- Enhanced Engine Longevity: Reducing wear and tear extends the life of critical engine components.

- Improved Fuel Efficiency: Engines that operate within ideal temperature ranges consume fuel more efficiently.

- Better Performance: Consistent oil temperatures help maintain optimal performance, especially in demanding conditions.

- Lower Emissions: Efficient engine operation often correlates with reduced emissions, making your business environmentally friendly.

Choosing the Right Cooler Oil Engine System

Selecting the appropriate cooler oil engine system for your diesel equipment requires careful consideration of several factors:

1. Understand Your Engine Requirements

The first step is to comprehend the specific needs of your diesel engine. Factors include:

- Engine Size: Larger engines typically need more robust cooling solutions.

- Operating Environment: Engines operating in extreme conditions may require advanced cooling systems.

- Usage Patterns: Heavy-duty use may necessitate a cooler oil engine with higher capacity.

2. Assess Cooling Capacity

The cooling capacity of the oil cooler must match or exceed your engine’s oil flow rates and heat generation needs. This ensures that it can effectively manage the temperatures under all operating conditions.

3. Quality and Reliability of Components

Opt for cooler oil engines made from high-quality materials. Steel or aluminum construction typically offers durability and efficient heat transfer capabilities. Additionally, verify the brand reputation and ensure equipped with appropriate manufacturer warranties.

4. Installation and Maintenance Guidelines

Proper installation and regular maintenance of your cooler oil engine system are paramount. Installation should be carried out by qualified technicians to ensure system efficiency. Regular maintenance involves checking for leaks, ensuring coolant levels are optimal, and replacing worn-out components as necessary.

Maintenance Tips for Cooler Oil Engine Systems

To maximize the lifespan and efficiency of your cooler oil engine, adhere to these maintenance practices:

- Regular Inspections: Schedule periodic assessments of the cooler oil engine to identify leaks or blockages.

- Flushing the System: Regularly clean the cooling system to prevent sediment build-up, which can hinder performance.

- Monitor Oil Levels: Keep an eye on engine oil levels to ensure there is enough lubricant working through the system.

- Replace Filters: Replace oil and coolant filters as part of your routine maintenance to maintain fluid purity and system efficiency.

Innovations in Cooler Oil Engine Technology

As technology evolves, so does the design of cooler oil engines. Innovations include:

- Smart Sensors: Integrated sensors that provide real-time data on temperature and pressure can help track system performance.

- Compact Designs: Advanced engineering techniques allow for more compact oil cooler designs without sacrificing performance, which is particularly beneficial for space-constrained applications.

- Enhanced Materials: Developments in material science are leading to lighter yet stronger oil cooler constructions that improve overall system efficiency.

The Role of Spare Parts Suppliers in Cooler Oil Engine Systems

For businesses in the diesel engine sector, having a reliable spare parts supplier is essential. Suppliers should offer:

- Diverse Inventory: Access to a wide range of cooler oil engine parts, including hoses, connectors, and various types of coolers.

- Expert Consultation: Knowledgeable supplier staff who can provide insights on the best products and solutions for specific diesel engine needs.

- Quality Assurance: Assurance that all parts meet manufacturing requirements and standards enhances the reliability of engine systems.

- Competitive Pricing: Suppliers that offer fair pricing on high-quality parts ensure that businesses can maintain profitability without compromising on quality.

Conclusion: The Future of Cooler Oil Engine Systems

In conclusion, the cooler oil engine system is a vital component in the operation of diesel engines. By maintaining proper oil temperatures, these systems enhance the longevity and efficiency of engines, positively impacting overall performance and emissions. Businesses involved in diesel engine maintenance and parts supply should prioritize understanding these systems, investing in quality components, and adhering to best practice maintenance protocols. Future advancements in technology will likely bring even greater efficiencies, making staying informed in this area increasingly critical.

At Client Diesel, we are committed to providing top-quality diesel engine parts and ensure that your operations run smoothly and efficiently. Explore our range of products to find the perfect solutions for your cooler oil engine needs.